Take on digital challenges in intralogistics intelligently

The once classic warehousing sector is facing challenges that can only be met with intelligent, digitally networked energy systems. With the "trak | uplift IQ" innovation solution, HOPPECKE shows how modern intralogistics can now become even faster and more efficient.

Anyone involved in intralogistics today will immediately notice with the unstoppable digital networking worldwide, expectations have risen - everything is to be handled ever faster and smarter. Whether it's individual orders on the net that will be with the customer tomorrow or the intelligent cooperation of people, goods, machines, plants and logistics: Industry 4.0 has long since arrived.

Global markets, which are also open to medium-sized companies, round-the-clock offers and an ever-increasing number of articles have changed logistics: It is no longer enough to simply move products from A to B - delivery time has become the decisive factor in competition. Logistics has long ceased to be a pure service; today it must be intelligently controlled and planned in order to be able to react immediately to changes.

For big tasks you need a lot of energy. It's good when it's always available

One industry that recognized this trend early on is the German automotive industry. Here, the right parts must be available just in time in the production process - for possible changes in the production sequence, so-called production islands, which are controlled by means of automated intralogistics, are therefore increasingly coming into play.

It has been shown that if you rely on the right technology - which includes more efficient battery management - you can make your processes more transparent and thus optimize them. With battery storage systems that reliably record all relevant data and key figures, work processes can be optimized in real time and controlled - regardless of location. In this way, digital logistics can not only provide more speed, but also save costs.

For the customers of HOPPECKE Batterien, the issue of energy availability in the context of intralogistics is extremely important, as Tim Kappe, HOPPECKE Sales Manager for the DACH (Germany, Austria and Switzerland) region, emphasises: "Forklift trucks and energy sources must be available reliably and safely at all times when goods have to be moved. The quality of corporate performance and competitiveness depend on this. It is therefore immensely important for us to accompany our customers in the digital transformation process and to find the perfect solution together with them".

The experts at HOPPECKE therefore developed trak | uplift IQ, an innovative energy system, consisting of battery, battery controller and charger, which can be easily extended to the HOPPECKE cloud solution, for example to use remote monitoring. Strictly speaking, trak | uplift IQ consists of three components which complement each other intelligently - or as the advertisement for a children's chocolate once said: "That's three things at once".

Time is money, as we all know. It is good to know how you can save it even more easily

An example shows at a glance how useful this technological innovation is: If a logistics or production manager uses a fleet of vehicles with different vehicles powered by batteries with different capacities and voltages, he can charge all sizes of batteries with one charger. The forklift truck driver no longer has to worry about which charger to use, thanks to trak | collect, the battery is immediately recognized by the charger. A further advantage: you benefit from the simple handling and avoid operating errors. And you can save money because fewer chargers are needed.

But the new offer is not only convincing from a logistical point of view, but also from a technical point of view: Thanks to optimized tubular plate technology HPzS, the newly used lead-acid batteries 2.0 with Active Carbon for increased efficiency require significantly longer water refill intervals compared to conventional lead-acid batteries. Water savings of up to 85% can be achieved, since, among other things, the optimization of the carbon content in the Active Mass means that less water is used. In addition, further optimizations regarding the charging factor and electrolyte mixing are also effective. Less refilling required means longer maintenance intervals and lower operating costs. Shorter charging times also save a lot of energy - and the battery is available more quickly.

A battery controller that thinks for itself. And shares its findings with you

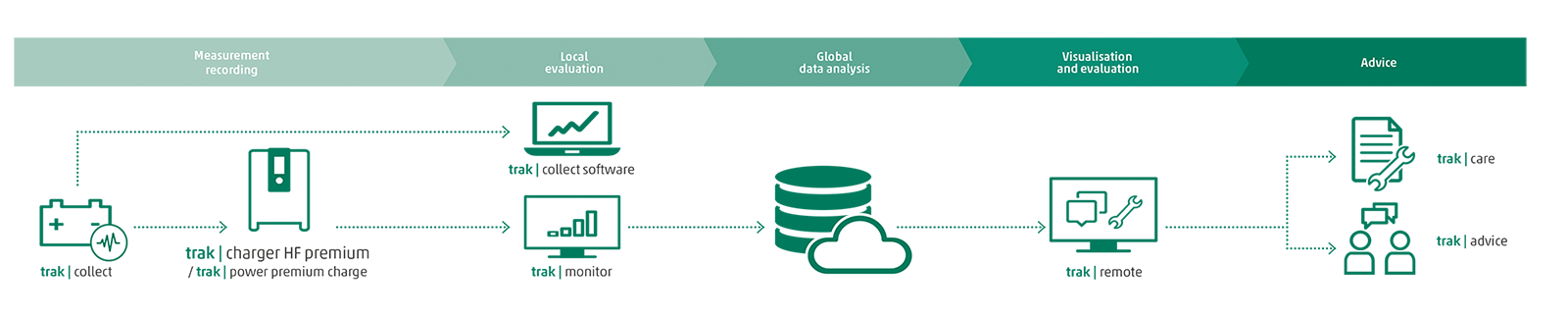

Equipped with trak | collect, probably the most intelligent battery controller on the market, this communication unit for lead traction batteries measures all relevant data, evaluates them and makes them available in a network. Up to five communication interfaces ensure that the current status of the battery is always known and that maintenance requests arrive in good time. trak | collect records the total battery voltage and the medium voltage of the battery, the charging and discharging current as well as the battery temperature and the electrolyte level. On this basis, the state of charge (SOC), state of usage (SOU), state of readiness (SOR) and current profiles as well as charged and discharged ampere- and watt-hours are determined and concrete recommendations for customers are derived.

Thanks to the trak | charger HF premium charger with adaptive charging characteristics, the highest possible energy efficiency is ensured: The charger's Smart Charge function ensures minimum water and energy consumption. Compared to conventional solutions, energy savings of up to 30% are possible. The high degree of efficiency also speaks for itself: energy savings of around 14% can be achieved in each charging process compared to previous 50 Hz chargers - an important contribution to reducing the carbon footprint and achieving climate protection targets.

When it comes to networking, the trak | uplift IQ system solution is also perfectly positioned to make intralogistics faster and more efficient. It is Fleet Ready and communicates with the battery environment. All relevant data is thus collected, analysed and stored locally or in a web-based remote monitoring system. Data can be collected locally and evaluated globally - in the spirit of Industry 4.0, which operates across all borders.

Preserves the environment, your budget and your nerves: trak |uplift IQ

For companies which rely on this intelligent battery management system from HOPPECKE Batterien for their intralogistics, there are a whole series of advantages: The reduced water and energy consumption means lower costs. The highest possible efficiency also ensures sustainable protection of our environment.

In addition, higher vehicle availability ensures greater flexibility and productivity in daily work. Cost-intensive downtimes are avoided, and logistical processes can be planned more safely and reliably. Communication with the battery environment - i.e. with a charger, PC or vehicle - also helps customers to professionalize their fleet management.

Thus "trak | uplift IQ" is particularly interesting for companies in the transport logistics, automotive and component supply industries and for all companies whose production logistics require a large vehicle fleet. But it is clear: "trak | uplift IQ" should be on the list of every expert in logistics and intralogistics when it comes to intelligent battery storage as the energy systems of tomorrow. Or as Tim Kappe of HOPPECKE sums it up: "We can offer customers long-lasting products with a long service life, which can be intelligently and efficiently networked. So, with "trak | uplift IQ" you are ideally equipped for the digitalisation of logistics, and you can work and plan more digitally, transparently and efficiently".