Over half of all forklift trucks and similar industrial vehicles in Germany are powered electrically, with most of them still using lead-acid batteries. With the trak | collect, HOPPECKE has the smartest control system on the market for lead-acid battery-powered forklifts. This system collects and evaluates all important battery data, and provides it via connected networks.

The trak | collect can be easily attached or retrofitted to all lead-acid batteries, and measures the battery status in real time to improve productivity and operational reliability. The system is especially suited to networked, digital logistics, as it enables high levels of flexibility and connectivity. Up to five communication interfaces are available. This makes it possible to evaluate battery data both locally and via remote monitoring, which can combine fleet and site data.

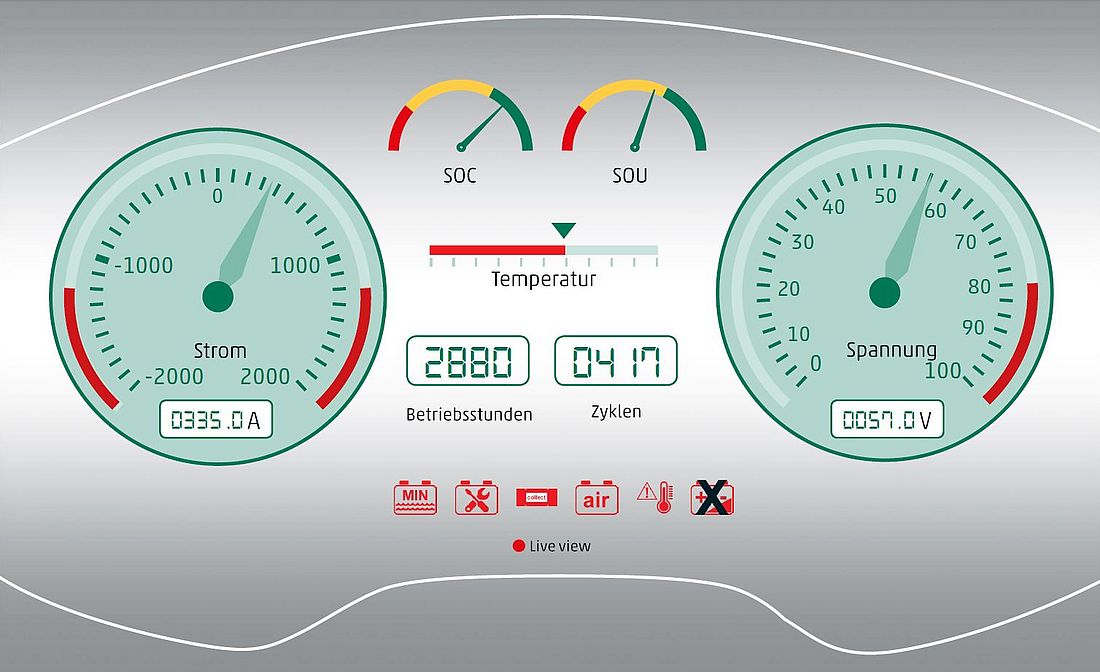

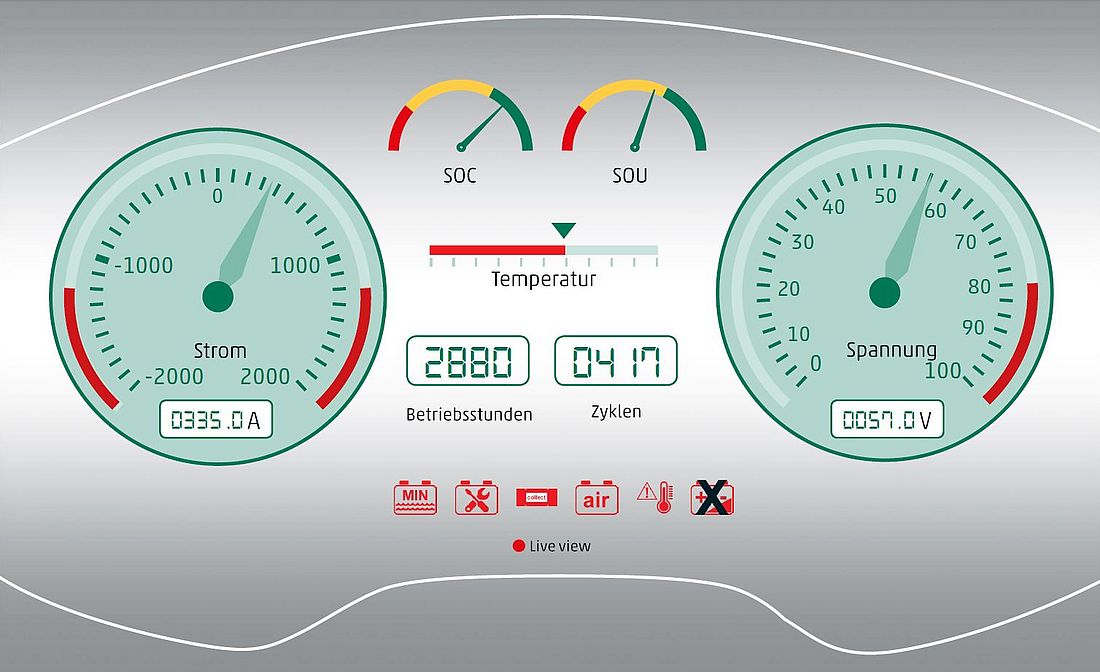

Once connected, trak | collect checks the battery's operational readiness and measures the battery voltage, medium voltage, charging and discharging current, battery temperature and electrolyte level. Based on this, the system measures the charge, usage and readiness states in real time, as well as current profiles and charged/discharged ampere and watt hours.

This battery analysis gives fleet managers access to information on battery errors and maintenance. It also enables more effective planning and analysis of deployment. All in all, this helps significantly reduce costs. Lead-acid batteries are not always easy to handle, but the trak | collect system allows users to operate and maintain them simply. This leads to improved performance and a longer service life.

The processed data is saved on the battery for local reporting. Thanks to its excellent connectivity, the HOPPECKE trak | collect can provide this data to the trak | charger, for example, in order to improve control of the charging curve. Data can be accessed via remote panel using NFC, Bluetooth, CAN-LIN and battery BUS interfaces. A smartphone app is also available for mobile applications. All this makes the new, smart battery control system an important tool in future intralogistics.

HOPPECKE will present the new trak | collect at the LogiMAT convention in Stuttgart from March 14 to 16.

Get your free ticket for the fair at the HOPPECKE LogiMAT Website

close

HOPPECKE trak | collect – Taking lead-acid batteries into the digital age

06.03.2017